High Voltage High-Speed Permanent Magnetic Machines: Cutting-Edge Technology for a Sustainable Future

In the realm of advanced engineering solutions, high voltage High-Speed Permanent Magnetic (HSPM) machines stand out as groundbreakers in the quest for innovation and sustainability within regulated industries such like power generation, oil and gas, petrochemical, transportation and renewable. They enable industries to reach new levels of efficiency, reliability, and sustainability compared to the conventional induction or synchronous counterparts. These machines represent the pinnacle of cutting-edge technology, offering a myriad of applications, while also presenting unique challenges and opportunities in the market landscape. Here, we delve into its status, applications, challenges, market, and trends shaping the industry’s low carbon emission future.

Applications Across Industries

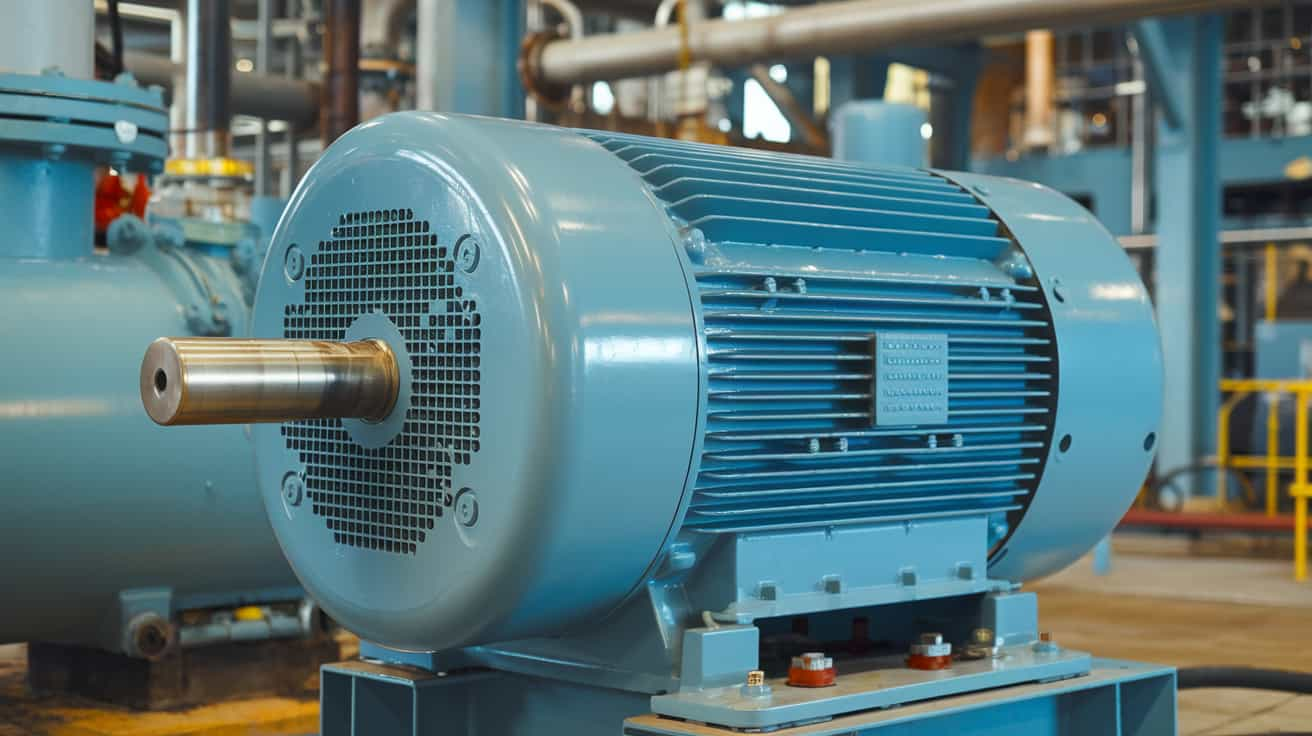

With the capability to achieve unparalleled speeds and operate at elevated voltage levels, the HSPM machines are redefining efficiency and performance standards in diverse applications. Their ability to operate at high speeds without auxiliary systems like gearboxes enhances reliability and reduces maintenance needs. The versatility of these machines extends across multiple industries, driving innovation in areas where efficiency and compactness are paramount.

- Renewable Energy: Used in wind and hydropower generation, these machines convert kinetic energy into electricity efficiently and are integral to scaling renewable energy solutions where the size matters.

- Industrial Manufacturing: In sectors like metals, mining, and petrochemicals, these machines power large-scale equipment, from compressors to turbines, facilitating high-volume, high-efficiency production.

- Transportation and Mobility: Electric vehicles, electric aircraft, railways, and marine vessels increasingly depend on these machines for propulsion systems, offering a cleaner and more efficient alternative to traditional electric machines.

- Oil and Gas: HSPM machines are essential in oil and gas for driving compressors and pumps, which operate in extreme conditions and demand high performance and durability.

Technical Challenges and Solutions

Despite their immense potential, the HSPM rotating machines face challenges related to thermal management, material durability, and system integration. Overcoming these obstacles presents an opportunity for collaboration between industry leaders and technology innovators to push the boundaries of what is achievable in sustainable engineering practices. Recent research in the HSPM machines focuses on improving their performance and technical readiness for industrial applications. Here are some key advancements:

- Electromagnetic Design: the HSPM machines face challenges such as managing cogging torque and parasitic losses. The cogging torque arises from changes in magnetic permeability as rotor poles pass stator slots, leading to pulsating torque that can affect performance. The electromagnetic analysis of the HSPM machines involves understanding the effects of power electronics and converter switching on machine performance, necessitating detailed modelling to predict performance accurately. The numerical analytical harmonic modelling includes evaluating induced electromotive force, electromagnetic torque, and rotor eddy current losses.

- Thermal Management: High-speed PM machines generate substantial heat, which can cause demagnetisation and reduce efficiency. Researchers have proposed composite rotor structures to enhance anti-demagnetisation capabilities and improve thermal management. The design must consider power loss distribution and fluid-thermal coupling analysis, used to analyse temperature distribution, to optimise cooling strategies. Proper material selection for components like the retaining sleeve can significantly influence thermal performance by minimising eddy current losses.

- Material Innovations: The rare-earth magnet does provide advantage for the PM machines operating at high speeds where traditional motors might suffer from increased losses. The use of advanced materials like NdFeB for surface-mounted PM structures has been explored to withstand high temperatures and improve mechanical performance, crucial for high-speed applications.

- Control Complexity: Precise control systems are required to manage synchronous operation and protect against faults. Developing advanced control algorithms and systems can enhance machine reliability and efficiency while managing complex operational demands. The HSPM motors often use VSDs (variable speed drivers) to adjust motor speed according to load requirements, leading to energy savings of 15-40% in applications like fans and pumps. This adaptability allows for precise control over energy consumption, reducing waste.

- Material Costs: The use of rare earth magnets, which are expensive, increases the overall cost of PM machines. The optimised rotor topology and design could use less rare earth material, delivering the same efficiency and power density performance.

Market Status and Trends in EMEA, USA, and China

The high-voltage, HSPM machine market has witnessed rapid growth over recent years, driven by the need of industrial electrification and decarbonisation.In Europe, Middle East, and Africa, government initiatives and policies encouraging renewable energy adoption, combined with a strong industrial base, have contributed to a substantial demand for these machines. Europe, in particular, is focused on the transition to clean energy sources, making HSPM machines essential to replacing conventional powering solutions. The market in EMEA was estimated to be worth several billion dollars in 2023 and is expected to grow at a CAGR of 5-7% through the next five years.

The push towards green energy, along with substantial investments in infrastructure, have led to a surge in demand for advanced high voltage HSPM machines in the United States. The USA's strong industrial and commercial sector, combined with the rise in renewable energy projects, supports a robust market for these high-performance machines. The market size is comparable to EMEA and is anticipated to grow slightly faster, around 6-8% annually, due to accelerated automation in manufacturing and increased focus on energy independence.

China leads in both demand and production of HSPM machines, fuelled by its large manufacturing sector and rapid urbanisation. China’s focus on reducing emissions has led to significant investment in renewable energy infrastructure, where these machines play a key role. The market here is projected to grow at a CAGR of 8%, driven by ongoing governmental “Dual Carbon” goal to support high-tech manufacturing and renewable energy.

Conclusions

The high voltage HSPM machines are a cornerstone of modern industrial, renewable, and renewable energy applications. With the global push towards greener and more efficient solutions, demand for these machines is set to grow across EMEA, USA, and China. However, industry players must overcome technical, regulatory, and cost challenges to fully capitalise on this opportunity. As the market evolves, advancements in technology, along with government support, will likely accelerate the adoption and impact of high-voltage, high-speed permanent magnetic rotating machines worldwide. By harnessing the power of innovation and sustainability, we pave the way for a future where cutting-edge technology propels us towards a more efficient and eco-conscious world.

Back